Welcome to our blog where we delve into the fascinating world of die casting and explore ways to improve efficiency in this essential manufacturing process. Die casting is a widely used technique for producing high-quality, complex metal parts with great precision. But did you know that the right mold accessories can play a crucial role in enhancing die casting efficiency? In this article, we will take a closer look at different types of die casting molds and highlight why mold accessories are so important. So buckle up and join us on this exciting journey as we uncover the secrets to optimizing your die casting operations!

The die casting process

The die casting process is a highly efficient method for producing metal parts with intricate shapes and complex geometries. It involves the use of a mold, typically made of steel or aluminum, which is filled with molten metal under high pressure.

The first step in the process is to prepare the mold by applying a release agent to ensure easy removal of the finished part. The molten metal, usually an alloy such as aluminum or zinc, is then injected into the mold cavity using either a hot chamber or cold chamber machine.

Once the molten metal has been injected into the mold, it rapidly cools and solidifies to form the desired shape. This cooling process can be accelerated through various means such as water-cooling channels within the mold or by using specialized cooling sprays.

After solidification, the mold is opened and the finished part is ejected. Any excess material, known as flash, is trimmed off before further processing or finishing operations are carried out.

Die casting offers several advantages over other manufacturing processes including high production rates, excellent dimensional accuracy, and repeatability. However, achieving optimal efficiency requires careful consideration of various factors such as mold design, temperature control during casting, and proper maintenance of equipment.

In our next section we will explore different types of die casting molds that can be used to enhance productivity and achieve superior results. So stay tuned!

Different types of die casting molds

Die casting molds play a crucial role in the die casting process, as they determine the shape and quality of the final product. There are various types of die casting molds available, each designed for specific applications.

One common type is the permanent mold, also known as gravity or chill casting. This mold is made from steel or iron and can be used repeatedly to produce high-quality castings. Permanent molds are typically used for small to medium-sized parts with intricate designs.

Another type is the sand mold, which uses a mixture of sand and binders to create a temporary mold. Sand molds are cost-effective and versatile, making them suitable for large-scale production runs.

Investment molds, also known as lost-wax casting molds, are another option. These molds are created by coating wax patterns with ceramic material before melting away the wax. Investment molds allow for complex shapes and detailed features but can be more expensive than other types.

There are graphite molds that offer excellent heat resistance and durability. These molds can withstand high temperatures during the casting process without warping or deforming.

Choosing the right type of mold depends on factors such as production volume, desired product characteristics, and budget constraints. It's essential to work closely with an experienced manufacturer who understands your specific needs when selecting a mold type for your project.

Understanding different types of die casting molds enables manufacturers to make informed decisions that optimize efficiency while producing high-quality castings tailored to their requirements.

The importance of mold accessories

Mold accessories may seem like small and insignificant components in the die casting process, but they actually play a crucial role in improving efficiency. These accessories are designed to enhance the performance of the molds and ensure high-quality castings.

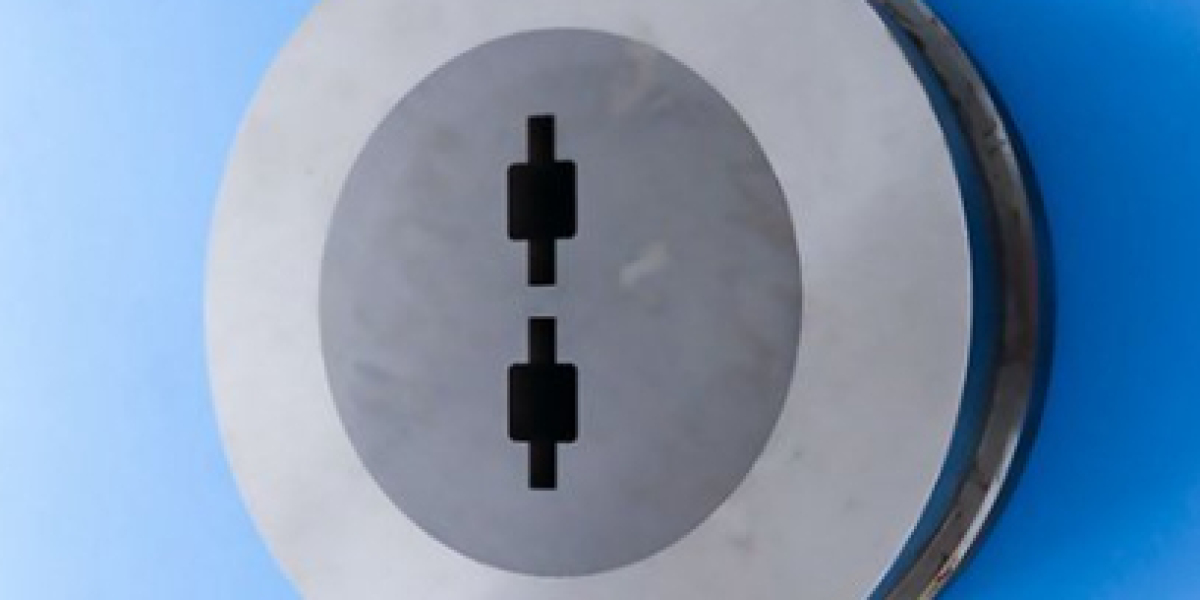

One important mold accessory is the ejector pins. These pins help in removing the casting from the mold cavity after solidification. By using proper ejector pins, you can prevent any damage to the casting or mold during ejection.

Another essential accessory is venting systems. Venting allows for the escape of gases released during metal injection into the mold cavity. Without proper venting, trapped gases can cause defects such as porosity or blistering on the surface of castings.

Sprue bushings are also vital mold accessories that aid in controlling metal flow into multiple cavities within a single tool. They help maintain a consistent flow rate and prevent any imbalances that could lead to defective castings.

Furthermore, cooling channels are necessary for efficient heat transfer during solidification. These channels allow for controlled cooling rates, which ultimately influence part quality and cycle time reduction.

Choosing and utilizing appropriate mold accessories is key to optimizing die casting efficiency while ensuring consistent production of high-quality castings. So don't underestimate their importance - these little components can make a big difference!

How to improve die casting efficiency

One of the most important aspects of improving die casting efficiency is optimizing the mold design. A well-designed mold can significantly reduce cycle times and increase productivity. One way to achieve this is by using advanced cooling systems that help dissipate heat more efficiently, such as conformal cooling channels.

Another key factor in improving efficiency is selecting the right alloy for your die casting process. Different alloys have different characteristics, including melting temperature and fluidity, which can impact both quality and speed of production. By carefully choosing the appropriate alloy, you can ensure better flow properties and reduce defects like porosity or shrinkage.

Additionally, proper maintenance of the mold is crucial for optimal performance. Regular cleaning and inspection can prevent issues like build-up or corrosion that could potentially affect product quality or cause downtime during production.

Furthermore, utilizing automation technologies like robotics or computerized control systems can greatly enhance die casting efficiency. These technologies not only improve precision but also minimize human error while maximizing throughput.

Investing in training programs for operators and technicians who work with die casting molds can yield significant benefits. Properly trained personnel will be able to identify potential problems early on and implement solutions effectively, resulting in improved overall efficiency.

By considering all these factors - from mold design optimization to material selection to maintenance practices - manufacturers can maximize their die casting efficiency and ultimately achieve higher productivity levels while maintaining consistent product quality.

Conclusion

The efficiency of die casting can be greatly improved by incorporating the right mold accessories. These accessories play a vital role in enhancing productivity, reducing defects, and ensuring consistent quality in the final castings.

By choosing the appropriate type of mold accessory for your specific die casting project, you can optimize cycle times, reduce scrap rates, and enhance overall operational efficiency. Whether it's thermal control devices to regulate temperature or ejector pins to facilitate easy removal of castings from molds, each accessory serves a critical purpose in maximizing die casting performance.

Furthermore, collaborating closely with experienced mold designers and manufacturers is essential to identify and implement the most suitable accessories for your specific requirements. Their expertise can ensure that you select the right materials and designs that align with your production goals.

Remember that investing in high-quality mold accessories may require an upfront cost but will ultimately yield long-term benefits through increased productivity and reduced downtime. So take the time to evaluate your current die casting processes and determine if any improvements can be made by incorporating suitable mold accessories.

In this fast-paced manufacturing industry where every second counts, optimizing die casting efficiency becomes crucial for maintaining competitiveness. By leveraging the power of the right mold accessories, you can achieve higher productivity levels while delivering superior quality castings consistently.

So don't overlook these small yet significant components - invest wisely in mold accessories today to reap substantial rewards tomorrow!